As I noted last year, we’re ramping up to return to Boston this July for our TC Sessions Robotics event. Our March 2020 event on the Berkeley campus was the last major in-person TechCrunch show before everything shut down. For what should probably be self-evident reasons, we decided that robotics is a subject best experienced up close, so we took 2021 off.

I’ve been champing at the bit for the past two years or so thinking about the programming for this one, and now that we’ve started the early stages, it’s hard to shut off the firehose. When we’re ready to start announcing guests, I’ll no doubt be devoting some column space to those folks.

Meantime, I’ve been thinking a lot about how the industry has evolved since this all started. I feel fairly confident when I say that future historians will point to this as the moment of great acceleration, when — after decades of talking about the future — robotics truly became a part of everyday life.

Some verticals are much further along than others, of course. Delivery is making quite a bit of progress — at least from the investment side. Regulation and implementation are a bit slower going. Understandably so. In addition to manufacturing — a longstanding application, especially in automotive — warehouse fulfillment has been white hot of late. Amazon got the ball rolling on that, and now the rest of the industry is trying to catch up.

Image Credits: RightHand Robotics

And then COVID happened. Then labor shortages. Then supply chain concerns. Decentralized logistics is really the only way to go these days, and those fulfillment centers are increasingly likely to be staffed by robots, like the pick and place machines created by RightHand, which just raised another $66 million.

The company’s funding is currently hovering around $100 million. It’s a healthy — but not wild — sum for a startup that’s got a lot of real-world hours under its belt. Among the long list of notable investors here is Zebra Technologies, which, as I noted yesterday, bought Fetch last year.

Image Credits: Ford/Agility Robotics

Oh, and while we’re talking both logistics and delivery, allow me to quickly plug my talk next week with Agility Robotics CTO Jonathan Hurst and PlayGround Global founding partner Bruce Leak. That’s Wednesday at 11:30 am PT / 2:30 pm ET. More info here.

Anyway, if you were to ask me which categories are on the cusp of breakthrough, I would give you two answers: agtech and construction. These are both massive industries with so much opportunity for automation. Agriculture, in particular, is an interesting one. It’s ripe for the proverbial picking. If you’ve read this far, you almost certainly understand how tough the category is, and we’ve seen some recent stumbles.

John Deere is pumping a lot of money into robotics, both through in-house development and acquisitions of companies like Bear Flag. For reasons of it being John Deere, it’s well-positioned to remain a major player in autonomous tractors. But labor shortages are a very real thing here — and the average age of a farmer in the United States is a few months shy of 60, for what’s often extremely back-breaking work.

The next several years are going to be wild for agriculture in general — particularly as climate change continues to be top of mind. It’s a subject that will likely increase interest in alternative approaches to the category, like the vertical farming we discussed last week. But the 10,000-year-old world of agriculture isn’t going to change overnight. In a sense, robotics offers a kind of way to retrofit existing ways of tending the land with new technologies.

Image Credits: Verdant

Given all of the advancements made to autonomy in recent decades, there’s a lot of opportunity there. And while you obviously need to make the systems safe, you’ve got far fewer points of failure in a field than your average city block. Verdant this week announced an $11.5 million raise, bringing its total to $21.5 million.

The Hayward, California-based company offers a robotic system that does a combination of laser- and spray-based weeding, coupled with taking scans of fields designed to give farmers more data on their crops.

“Farmers told us not to give them more data, but to figure out what to do with the mountains of data they already have, or better yet just go do it,” co-founder and CEO Gabe Sibley said. “They want a complete solution that takes action in real time and keeps farmers in control — all while improving profitability and automating dangerous, back-breaking field work.”

Image Credits: Leko Labs

Construction is another category that’s ripe for some massive robotic disruption. I say that as a resident of a city that’s seemingly constantly under construction — so if you could build some quiet robots to do some of the work, that would really help me out. Anyway, Natasha had the story this week about Leko Labs’ $21 million Series A. The firm is working to bring more sustainable materials to home construction, using an “automotive style, robotics driven” approach.

Image Credits: Hyphen

I wouldn’t put kitchen automation at the top of the list, but it’s certainly one that has been catalyzed by the pandemic in a major way. Two years in, and restaurants are having as hard a time as ever staying staffed. We wrote about Hyphen in this very newsletter as the startup came out of stealth, and this week it announced a $24 million Series A led by Tiger Global for its modular conveyer belt kitchen system.

The system specializes in bowls/salads, which is probably what you want your robot to be cooking if it’s not trying to make pizzas and/or flipping burgers. Also, a quick mention for Dexai Robotics, which signed $1.6 million contract to bring its cooking arm, Alfred, to U.S. military installations.

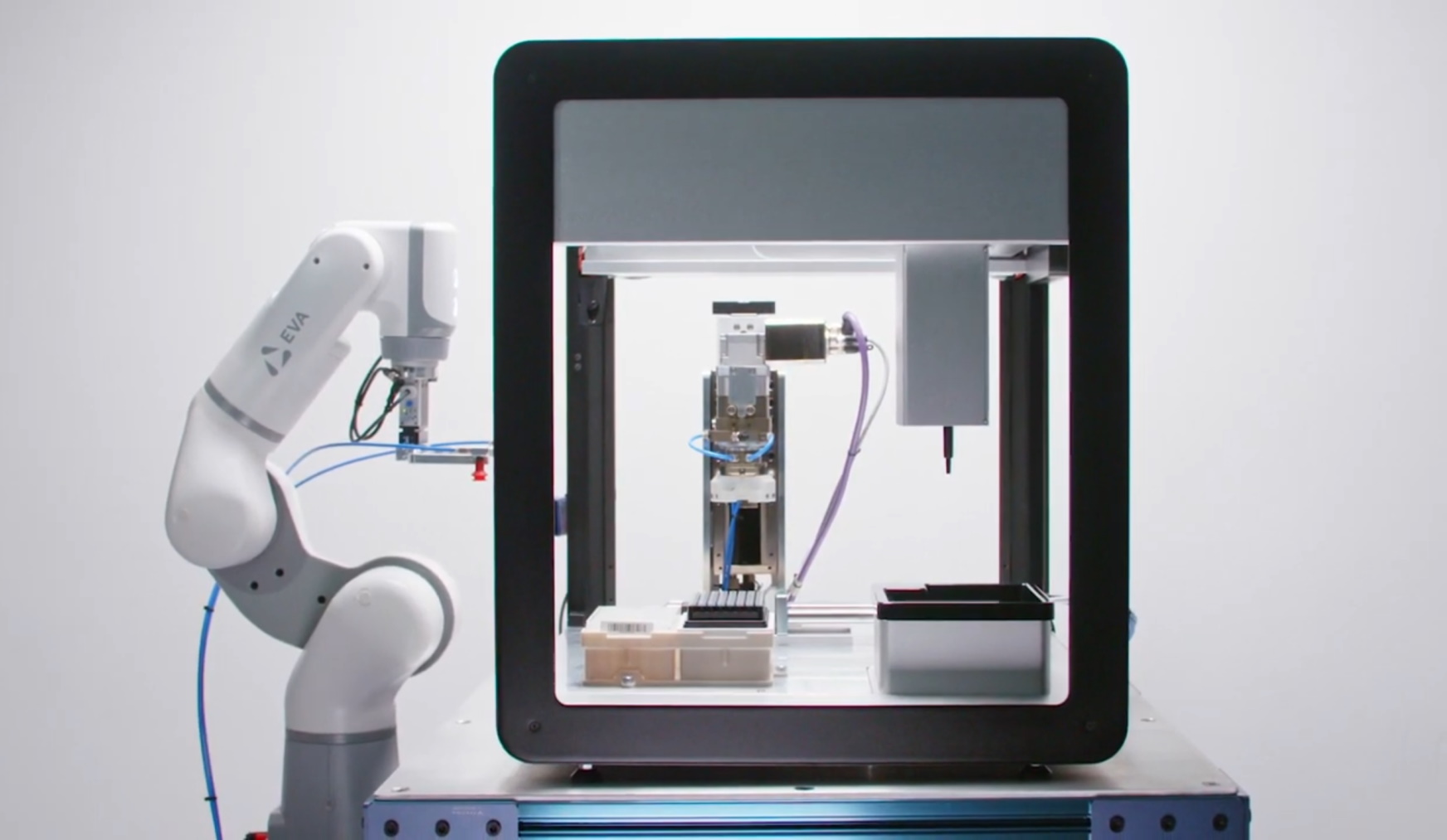

The Automata Labs enclosure with Eva robotic arm next to it. Image Credits: Automata

Automata is something of a dark horse this week. Lab automation isn’t something we’ve covered much in this newsletter, but COVID has really shone a light on the need for rapid lab results. The firm this week announced a $50 million Series B aimed at fully automating the laboratory process.

“We’ve had to build an entirely new hardware stack that allows for this kind of automation,” co-founder and CEO Mostafa ElSayed told Devin. “The benchtop is really the standard unit of all laboratories, so it’s basically a whole lab bench that’s amenable to automation.”

And finally, the real automation we’re all waiting for. Here’s Amazon’s Astro bringing someone a beer. The expensive home robot recently started shipping out to customers.

Image Credits: Bryce Durbin/TechCrunch

This free weekly robotics newsletter is just a signup away.